Veneer Grade Quarter-Sawn Flooring

(also called vertical quarter-sawn or perfectly quarter-sawn)

QUALITY: Our flooring starts with the finest logs possible, only veneer grade logs are used in our production. About 1 in 500 trees are veneer grade. You simply cannot build the finest wood flooring possible if you don’t start with the finest logs. We then designed and custom built a radial-sawmill, a sawmill in which every board is vertically grained.

STABILITY: Did you know that there are over $1 Billion dollars per year in claims against wood flooring manufacturers? This is because wood is hygroscopic – it expands when moisture (humidity) is present. If this is not taken into account when buying your floor, you could be in for a bad surprise. Recent design trends of the last 30 years, such as wide plank flooring and alternative heating systems, such as radiant heat, have contributed to these failing floors.

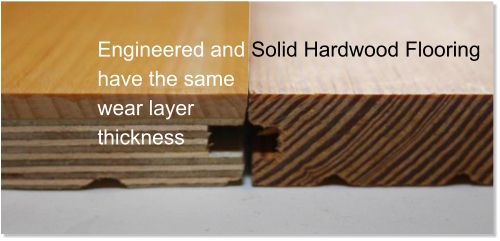

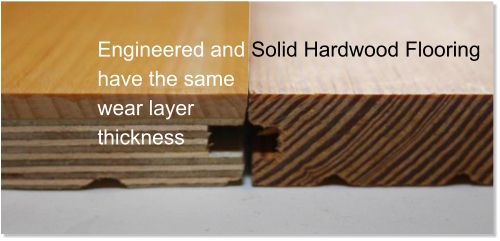

Do not fear, properly specified wood flooring will last your lifetime, as it has done for 100’s of years. To further increase the stability of wood flooring (beyond using vertical grained wood), our industry has designed “Engineered” flooring. Just like the laminated beams and floor joists used in your home, laminated constructed flooring uses the same cross banding of wood plys to increase the stability of your wood flooring. Our engineering process uses an industry high total of 12 cross-banded plys in the construction of your floor, yet, we still have the same amount of usuable wood as does a solid wood floor.

Due to the shear strength required to fracture our 12 ply construction and due to our vertical grain hardwood wear layer, we have the most stable flooring in the world. Due to the shear strength required to fracture our 12 ply construction and due to our vertical grain hardwood wear layer, we have the most stable flooring in the world.

BEAUTY: Please read our article on Chatoyance to understand why a vertical grain board has a higher light reflectivity than a board sawn any other way. This nature of wood holds true for all species of flooring, White Oak, Red Oak, Hard Maple, Walnut and Cherry.

NOFMA Classic Grade Engineered Flooring

Properly manufactured engineered flooring has sucessfully been in use in the most difficult climates/installations here in the U.S. for well over 10 years now. This product has been effective in wider widths than it’s solid flooring counterpart. If the interior climate of your home will have a relative humidity (RH) range greater then 20% over the course of a year, you should consider using a well made engineered floor. Please view our Standard Grade Engineered Flooring products here.

NOFMA Classic Grade Solid Flooring What can we say, this product has been in use for the last 80 years. Typical lifespan for this type of flooring is approximatly 40 years. Prior to the 1960’s and the advent of air conditioning, solid wood flooring used to be limited to 2-1/4” and 3” widths (and with Maple that moves more with humidity changes, 1.25” widths were common). High end floors back in these days were quarter-sawn yet still only in narrow widths. With the introduction of air conditioning, which reduced the interior humidity of homes during the humid seasons, we now see solid wood flooring in widths up to 9” (called wide plank). The consumer must be very careful when specifing solid flooring in widths exceeding 4”. These decisions need to be made based upon a careful assesment of the range of humidity at the level of the floor that the house will be subject to “in the worst case”. Please follow the link “Flooring Width Selection” for a detailed discussion on this subject. The three areas of concern in deciding plank width are: 1) Range of Relative Humidity (RH) inside and outside the home; 2) Type of heating & cooling system in use in the home; and 3) The sub floor beneith the hardwood floor.

|

Due to the shear strength required to fracture our 12 ply construction and due to our vertical grain hardwood wear layer, we have the most stable flooring in the world.

Due to the shear strength required to fracture our 12 ply construction and due to our vertical grain hardwood wear layer, we have the most stable flooring in the world.